Ugh. I ran the botom end up to Hawg’s last week so we could press out the fly wheels a generaly asses the stat of the bottom end. First I want to say sorry that I dont have any pictures. The subject completly sliped my mind. durring this whole process. What I will say though is that the proccess was rather enlightning and edjucational. To Hawgs I took the left case , fly wheels, and the gouged piston. The first thing Hawg did was to look at the piston and say “look how the ware goes at an angle to vertical.” Damn he knows what hes talking about. 🙂 So after some shit shooting and finding tools we got the flywheel pressed out of the case.

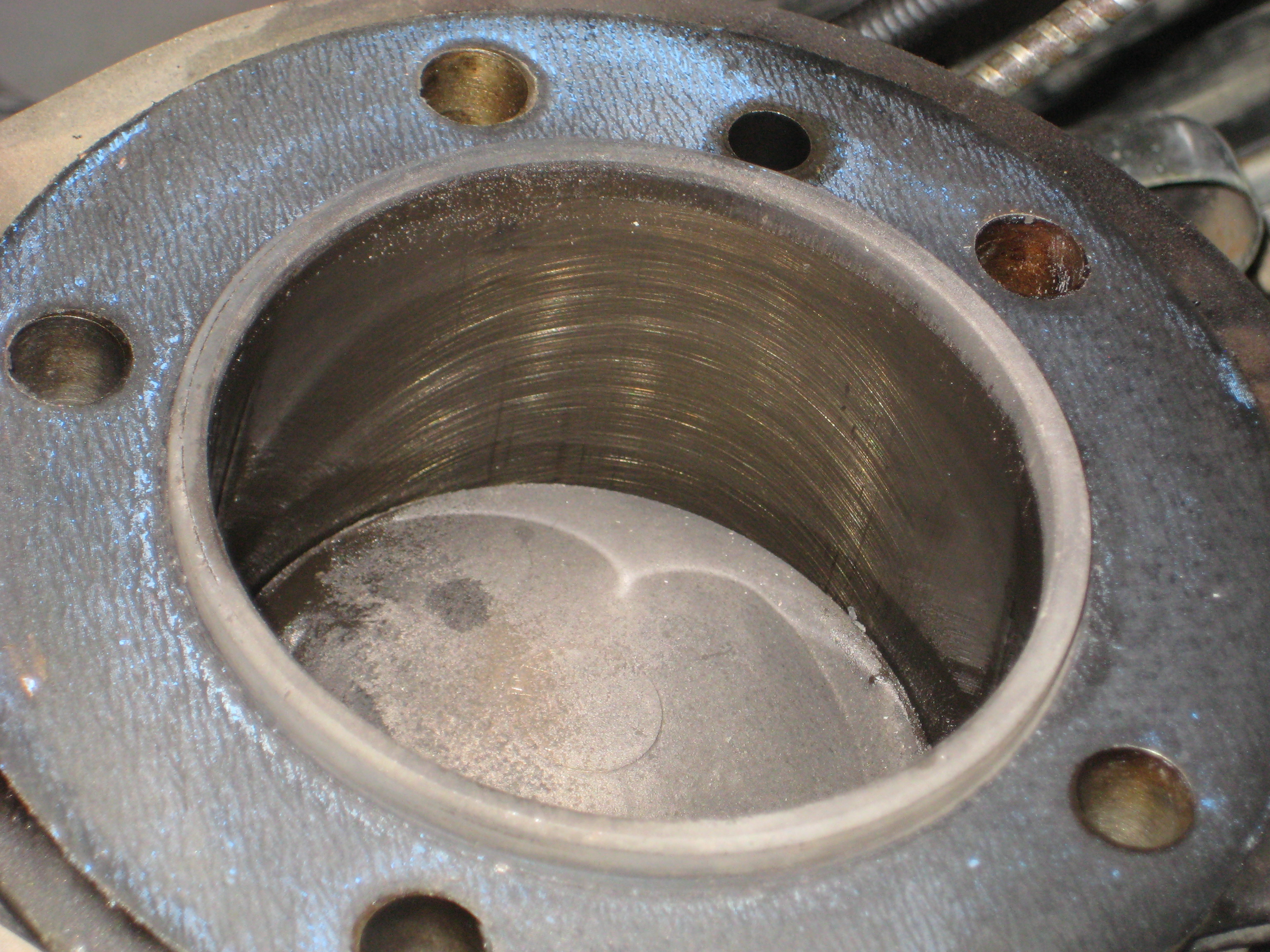

We found some interesting things. First the connecting rods had been pushed over into the thrust washer left thrust washer to the pint that it had gouged into it. Can it be fixed ??? Then we found that the connecting rods were vary difficult to get off of the drive crank pin. But we did get them off. What we found after we got the flywheels apart was nothing liess then disappointing. First the right flywheel was bored, drilled for balancing, at the top, neer the crank pin. This is a NO NO as it weakens the wheel and leads to cracking. Next we found that the borring holes on the left wheel were drilled out then refilled with lead. In of of itself is not bad but when ist is just half assed into the hols it leads to the lead falling out of the holes. As in this case. We speculate that it was the leaching lead the lead to the connecting rods feeling so gummy and hard to pull off the crank pin. Lastly we found that the crank pin and bearings were pitted and there for no good.

So last Tuesday the 12th, since there closed on Mondays (hours are helpful on the webpage). I took my engine up to the machine shop and Billy said my cam was shot as well. Now I’m looking at not only a $1200 top end rebuild but a bottom end as well. The parts alone for the bottom end is in the $1000 rang just for the fly wheels. So in about three more weeks I hope to hear from Billy about a quote on the engine rebuild.

- Valve job – $650

- Cylinder sleeve and boring – $625

- Bottom end rebuild – $1000

- Original 1968 Slab Shovel with OEM case and jugs – Priceless

Now fortunately I have time to check the trans and swing arm as well as rewire marlin.