Gears

Posted in Engine, repair, The Long Rode on March 15th, 2013 by WadeToday I received the gaskets for the oil pump. So I put it together Problem is that yesterday I ran all over looking for woodruff keys (#207) and locking rings. See when I ordered the gasket kit I thought it was just the gaskets. I ended up having to get the woodruff keys from the local HD shop for $3 apice, McMaster-Carr sells them for $0.23 apice in quantities of 50. This morning I went and got the keys. Then in the mail was my gasket kit. Luckily the kit was a full rebuild kit with two keys and the locking ring in it. So tomorrow I get to return the keys and the locking ring. Whoot.

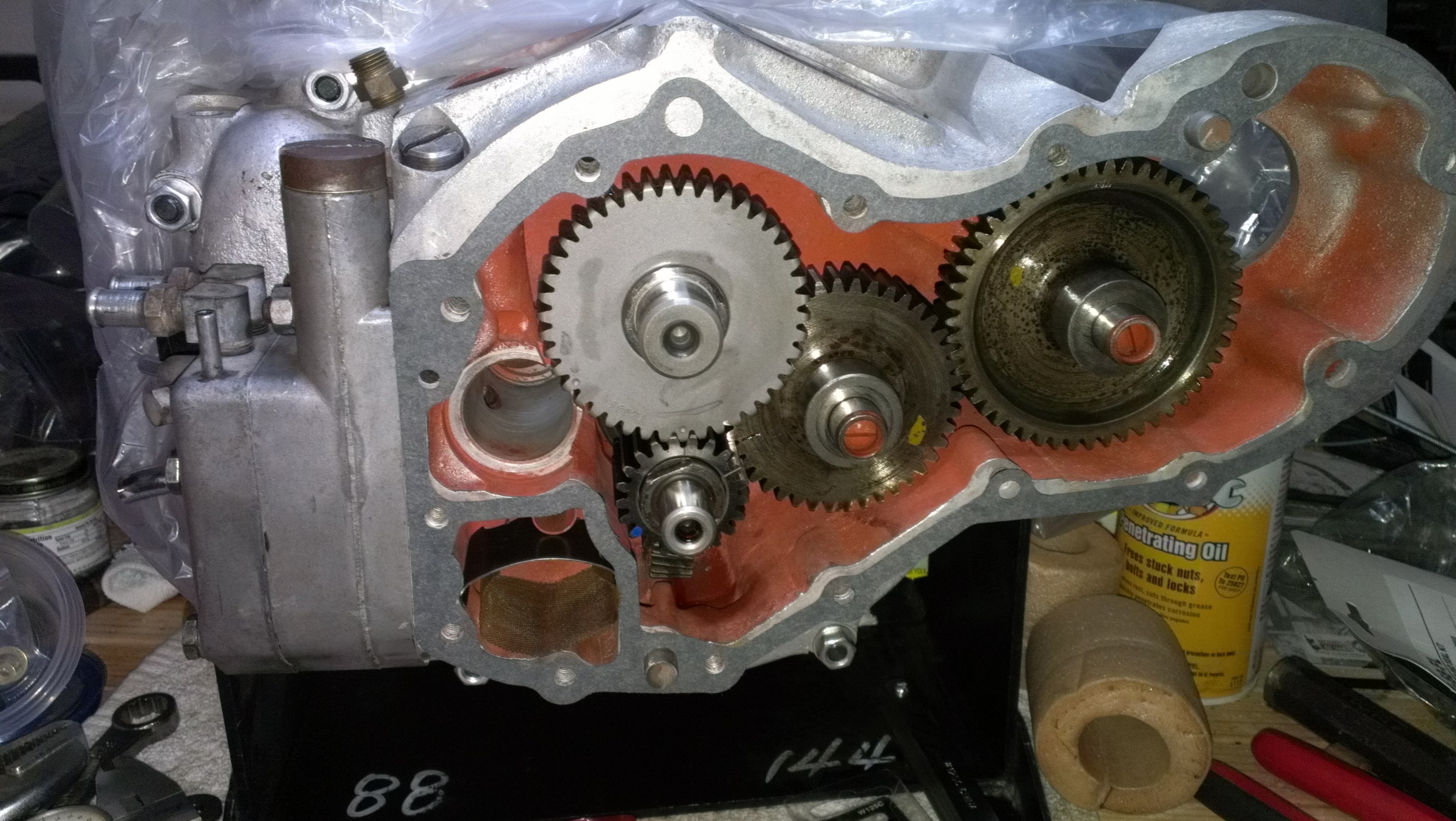

With the oil pump rebuilt and installed I started on the gear case. This is where I ran into a new problem. I got all the gears set in place and the only one left was the breather gear. When I looked inside the breather I could see some caked on gunk. A couple of large pieces of lead came out wich made me think it was caked with lead. This started the process of trying to clean the breather. Since the stupid things coast $120 I figured this was the way to go.

If you look close at the second picture you can see the hols at the bottom of the breather are clogged. So I tried to take it appart. I was able to pry off the retaining clip seen in the first pic. But I could not get the screen out to clean it. I finally decided to chisel it out and grab it with a pair of pliers. This worked and would have been easy to reshape to fit back into the breather. But of course it would not be that easy. Once I got the screen out it was not only caked it was fused. I think it had rusted out inside the breather and got caked with lead. A pice about the diameter of a penny broke off the screen.  So tomorrow I get to try and find some perforated sheet metal that will replace the breather screen along with a way of securing it in the breather.

So tomorrow I get to try and find some perforated sheet metal that will replace the breather screen along with a way of securing it in the breather.